What is Accuspect?

The intelligent multi-frequency eddy current flaw detector adopts the most advanced FPGA and DSP digital processing technology to realize real-time multi-frequency eddy current detection, which can effectively detect defects in metal materials. Its accuracy and speed exceed the existing mainstream products. ACCUSPECT can preset parameters and expert programs according to user needs. It is easy to operate, with an intuitive man-machine dialogue interface and touch screen.

What is Eddy Current Testing?

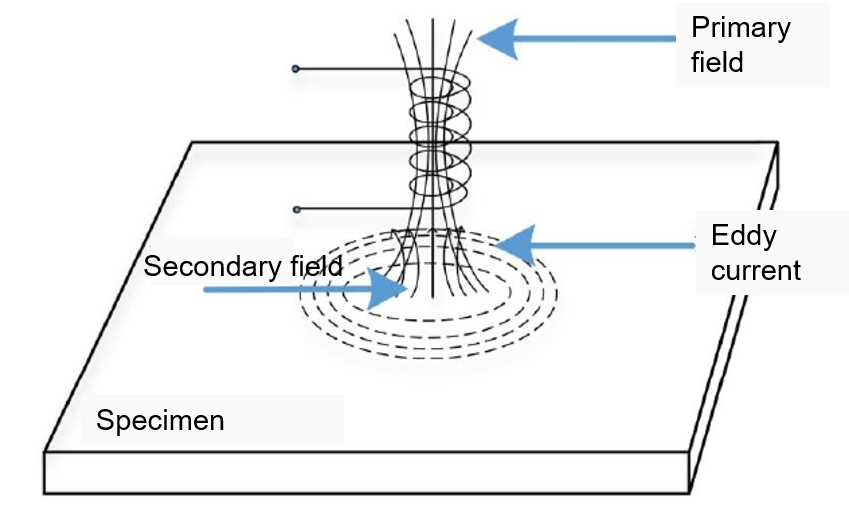

Eddy current testing is one of the most widely used non-destructive testing techniques in industrial applications. An alternating current is injected into a coil to generate a corresponding alternating magnetic field, which is called the primary magnetic field. For a specimen made of a conductive material, eddy currents are induced in the specimen.

The eddy currents in the specimen will induce a magnetic field, called the secondary magnetic field, which opposes the primary magnetic field and reduces the magnetic flux existing in the coil, resulting in a change in coil impedance.

When the sensor scans across the defect, the eddy current will be disturbed due to the discontinuity of the conductivity caused by the defect. Therefore, the secondary magnetic field induced by the eddy current field changes. Besides, since the excitation frequency and the injecting current keep the same, the primary magnetic field remains unchanged.

Hence there is a change in the coil impedance due to the presence of the defect, which is manifested as a change in the amplitude and phase of the detection signal in the detection impedance diagram.