Accuspect Technology

Portable, Multi-Frequency NDT Solutions

Introducing the latest in ruggedised, field ready

non-destructive testing solutions.

Scroll Down to Learn More

By continuing to browse this site you agree to our privacy policy.

Agree & ClosePortable, Multi-Frequency NDT Solutions

Introducing the latest in ruggedised, field ready

non-destructive testing solutions.

Scroll Down to Learn More

Data speed up to 10k frames per second

1 - 64 Channels

Up to 95% detection rate for defects > 2mm

Extendable sensor for hard to reach locations and hazardous environments

Channels, storage capacity, frequency range and more can be customised and adjusted

Founded by a UK Research and Development team and academics from the University of Manchester, Accuspect specialises in the application of eddy current NDT&E in various industrial sectors.

The company has successfully launched their first product- ACCUSPECT, multi-frequency portable Eddy current NDT device and it can also provide bespoke EM online inspection solutions meeting customers’ specific requirements

Learn More....jpg)

Our Innovative, Ruggedised, Field Ready NDT Solution

Our First, All-In-One, Multi-Frequency NDT Solution

For the applicatipon of lower conductivity composite material, we developed high frequency version of ACCUSPECT NDT Solution

Accuspect, the intelligent, multi-frequency eddy current flaw detector adopts the most advanced FPGA and DSP digital processing technology to realise real-time, multi-frequency eddy current detection, which can effectively detect defects in metal materials.

Its accuracy and speed exceed the existing mainstream products. Accuspect can utilise preset parameters and expert programs according to user needs. It is easy to operate, with an intuitive man-machine dialogue interface and touch screen.

Learn more about our products and review technical information in our Product Portfolio

We are pleased to introduce the next in our product range, the Accuspect-M. This builds on our original product to offer simultaneous, Multi-Phase testing. Get in touch via our contact form to enquire about availability and pricing.

Automatic identification, imaging, and qualitative analysis of defects can be performed in real time and in-situ, avoiding the tedious and time-consuming steps of bringing samples back to the laboratory for inspection.

The tested sample does not require additional surface polishing, cleaning, and levelling treatment; both cylindrical and flat samples can be measured.

With fast test speed and high detection accuracy, the builtin algorithm can minimise the external environment and electromagnetic interference , suitable for the complex and diverse test environment of the power plant.

We can design multi-channel or array probes for large-area scanning for different application scenarios, effectively improving detection efficiency.

The user interface of the equipment can be flexibly customised, and the operation is simple, and the evaluation results can be obtained automatically and quickly based on the measurement data.

High-Definition touch IPS display screen

Support for English, Chinese and other languages requested

Multiple intelligent automatic detection and alarm methods

Multi-frequency, multi-channel eddy current testing

Fast and high precision electronic balance

Adjustable probe excitation amplitude

Multi-track impedance plane and time-base scan display

Built-in high performance solid-state lithium battery (can work continuously for up to 10 hrs)

USB and network interface

Programmable, dedicated process parameters

Real-time data storage and database management

Unique crack analysis function

Accuspect has applications across a wide range of industries. Click the cards below to learn more:

.jpg)

Metal Classification

Recycling automotive, electronic, and other end-of-life waste liberates large quantities of metals, which can be returned to the supply chain. Sorting the nonferrous metals, however, is not straightforward.

The frequency response of electromagnetic (EM) sensors is closely related to the electromagnetic properties(conductivity and permeability) of the metals:

The magnetic field induced in an object, in response to different frequency excitation magnetic fields.

This induces eddy-currents to circulate in the object, which in turn induces a secondary or scattered magnetic field

Therefore, EM methods can identify and sort nonferrous scrap efficiently and economically.

Security

Walk-through metal detection (WTMD) has proven to be a fundamental part of the screening of large numbers of personnel for potential threat objects and WTMD use is widespread in locations such as airports, prisons, embassies, ports and government buildings.

It is required to detect prohibited metallic items such as knives, guns and components of explosive devices out of a secured area.

EM methods typically rely upon the heuristic analysis of peak signal responses from an array of coils, and relating these to their approximate locations.

.jpg)

CFRP

Carbon fibre reinforced polymer(CFRP) is an extremely strong and light fiber-reinforced plastic which contains carbon fibers. CFRPs are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications.

Structural health monitoring (SHM) of the CFRP, such as missing carbonfibre bundles, lanes, suspensions, fringes, missing sewing threads, angle errors and hidden manufacturing defects, is an invaluable quality control.

EM testing can be applied to monitor the structural health and detect defects of CFRP due to its contact-less, noninvasive nature.

.jpg)

Multi-Phase Flow

In fluid mechanics, multiphase flow is the simultaneous flow of materials with two or more thermodynamic phases.

Multi-phase flow imaging is a challenging topic in industrial process tomography.

Magnetic induction tomography (MIT) is sensitive to the conductivity of the target, and as such has the potential to be used as an imaging technique to visualise the conductive components in a multi-phase flow application.

.jpg)

Bio Medical Imaging

Eddy current analysis could provide an indication of conductivity change within a biological body. EM testing is noninvasive and contactless technology and especially attractive for possible biomedical applications, for example intracranial hematoma monitoring and brain tumor detecting.

Food Inspection

Ensuring the highest product quality and safety for brand and end user protection is very important in food industries. Final inspection of products at the end of the production line is the last line of defense to detect any foreign bodies before shipping to retailers and supermarkets.

EM methods are capable of detecting the physical contamination due to the different conductivity between the food and the foreign bodies.

Non-Destructive Testing

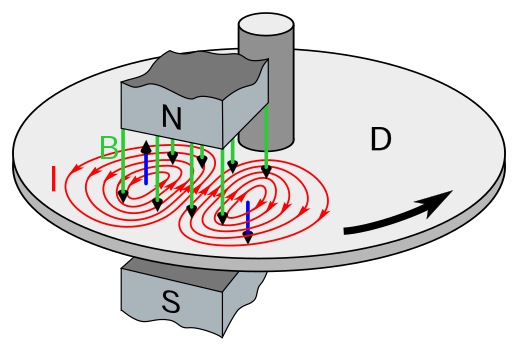

Eddy-current testing is one of many electromagnetic testing methods used in nondestructive testing (NDT) making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials.

Excitation coil produces an alternating magnetic field around itself. When the coil approaches a conductive material, currents opposite to the ones in the coil are induced in the material — eddy currents.

Variations in the electrical conductivity and magnetic permeability of the test object, and the presence of defects causes a change in eddy current and a corresponding change in phase and amplitude that can be detected by measuring the impedance changes in the coil, which is a telltale sign of the presence of defects.

ECT has a very wide range of applications in the aerospace industry and in other manufacturing and service environments that require inspection of thin metal for potential safety-related or quality-related problems.

Demining

Anti-personnel mines remain a global challenge with contaminated land estimated to be 300 𝒌𝒎^𝟐 world-wide.

The main challenge for landmine detectors has shifted over the last decade towards the classification of metallic content as opposed to detection.

Typical electromagnetic induction (EMI) sensors are composed of an excitation coil which generates a primary magnetic field and a receive coil used to measure the induced fields caused by interactions with surrounding material. Eddy currents generated in the metallic target as a result of the time-varying primary field are dependent on a number of parameters such as size, shape, material and location.

.jpg)

Steel Production

In the manufacturing of steel strip for the automotive sector, the mechanical properties are largely defined by the process conditions in the hot strip mill. In particular the phase transformation, from austenite to ferrite, which takes place during the forced cooling stages on the run out table (ROT) after the finishing mill, governs the microstructure and hence the mechanical properties.

At present, there is no direct method for monitoring the steel microstructure transformation online; However, the EM method is an attempt to make direct measurement of the micro- structure, and has particular virtues, for instance, being non-contact, having a fast response, being unaffected by water and dust, and having low cost.

Recycling automotive, electronic, and other end-of-life waste liberates large quantities of metals, which can be returned to the supply chain. Sorting the nonferrous metals, however, is not straightforward.

The frequency response of electromagnetic (EM) sensors is closely related to the electromagnetic properties(conductivity and permeability) of the metals:

The magnetic field induced in an object, in response to different frequency excitation magnetic fields.

This induces eddy-currents to circulate in the object, which in turn induces a secondary or scattered magnetic field

Therefore, EM methods can identify and sort nonferrous scrap efficiently and economically.

Get in touch today. Simply fill out the form below or give us a call to speak to a member of our expert customer care team.

We are based on Pride Park in the heart of Derby, UK.

Accuspect Technology is a trading name of TrainFX Ltd. (C) 2020 - All Rights Reserved